Aircraft airframe noise: Blowing for bluff-body noise control

Last updated on April 5, 2022

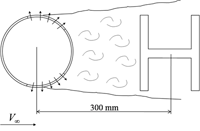

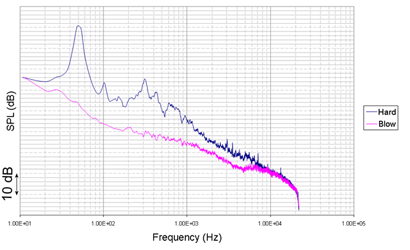

Landing gear noise is a major contributor to airframe noise. Wakes from upstream components impinging on downstream components are a significant source of noise. This work investigates the use of flow control to reduce the noise generated by bluff bodies. After the bluff body demonstration case the flow control was applied to an aircraft main landing gear. The aim of this work was to assess and develop local blowing flow control methods for bluff body noise reduction. The first demonstration case was on isolated components, i.e., a cylinder and an H-beam. A tandem configuration of an H-beam and a cylinder was used to investigate interaction noise between two bluff bodies. For the isolated components a pneumatic split plate was investigated. A small jet was applied on the rearward face 180 deg. from the stagnation line of two bluff bodies to provide an analogous reduction in bluff body noise to that achieved with a physical split plate. For the interaction case the flow control was applied to the cylinder to break down the large flow structures and to displace the peak turbulence away from the surface of the downstream component.